Exploring Milling Machines for Sale: A Comprehensive Guide

Understanding Milling Machines

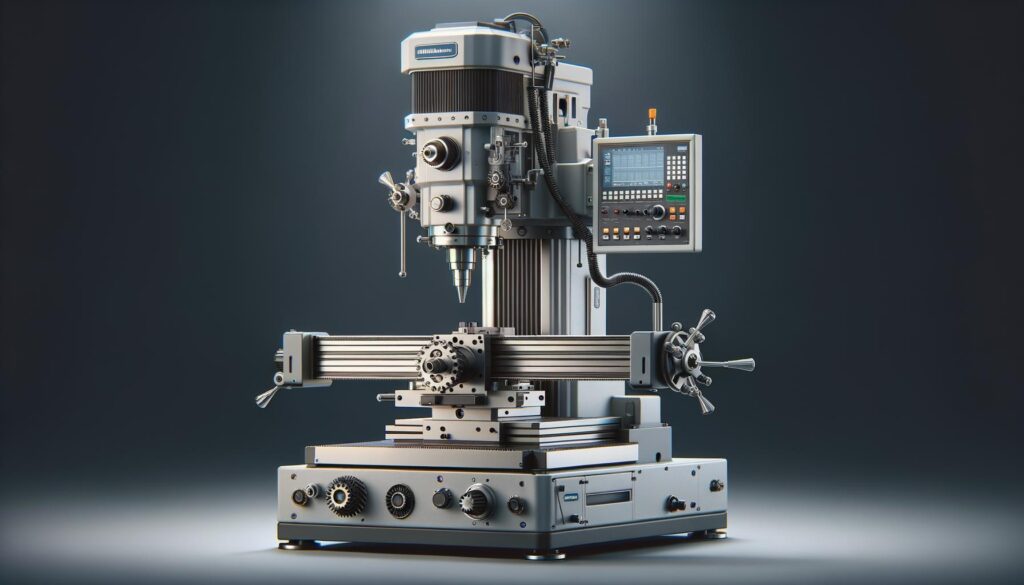

Milling machines are a staple in the manufacturing industry, serving as versatile tools for shaping and cutting metals and other materials. These machines come in various types, each suited for specific tasks or preferences. To make an informed decision when purchasing a milling machine for sale, it’s essential to understand the differences between horizontal and vertical mills. Horizontal mills have their spindles aligned horizontally, suited for cutting heavier materials or large volume production. On the other hand, vertical mills with vertically aligned spindles offer greater visibility and ease of use for detailed tasks.

A milling machine’s capabilities are further expanded by its additional features. Considerations include the machine’s axis configuration, which determines its range of movement, such as a 3-axis or 5-axis setup. Additionally, CNC (Computer Numerical Control) technology is an asset for complex, automated machining processes, adding precision and reducing manual input.

Identifying Your Needs

A key step in purchasing a milling machine is evaluating your specific requirements. Factors to consider include:

- Project Scope: Determine whether the machine will handle small, intricate work or heavy-duty tasks.

- Material: Understand the types of materials you’ll be working with, as different machines are optimized for metals, plastics, or composites.

- Space: Consider the physical space where the machine will be placed, ensuring it fits and operates efficiently in your workshop.

- Budget: Set a realistic budget, keeping in mind the potential need for additional tooling or accessories.

Matching the machine’s capabilities to your needs ensures that you make a purchase that is both cost-effective and functional over the long term.

Exploring the Marketplace

When searching for a milling machine for sale, the marketplace offers both new and used options. New machines often come with warranties and the latest technology, offering peace of mind and reliability. However, the cost can be significantly higher compared to used machines. Used milling machines provide an attractive option for those on a tighter budget but require careful inspection for wear and tear.

Consider purchasing from reputable dealers who can offer machine history, usage details, and after-sales support. Online marketplaces and machinery auctions are popular venues, but it’s essential to verify the credibility of sellers and the condition of machines through reviews and ratings.

Evaluating Features and Specifications

Understanding the detailed specifications of potential machines is crucial. This includes the spindle speed, feed rate, and motor power – all of which impact a milling machine’s performance. Spindle speed determines the cutting speed, while feed rate affects the quality of the cut and overall efficiency. Motor power relates directly to the machine’s ability to cut through dense materials without stalling.

Furthermore, examine the machine’s table size, as this influences the maximum size of workpieces it can accommodate. Don’t forget to look into the software compatibility if you are considering a CNC milling machine, as this dictates the ease of integration with your existing production processes.

Making an Informed Decision

The final step in finding a milling machine for sale is making an informed buying decision. Weigh the pros and cons of each option, considering the balance between cost and functionality. Ensure the machine meets your technical requirements and factor in the availability of service and support.

Look for customer testimonials and industry reviews to get a sense of satisfaction and any potential issues that might arise post-purchase. Don’t hesitate to reach out to industry contacts or forums for advice and experiences from other users.

Conclusion: Finding the Right Milling Machine for Your Needs

Purchasing a milling machine is a significant investment that requires careful consideration of various factors, from understanding different machine types to evaluating your needs and exploring the market. By taking the time to conduct thorough research and assess all aspects of potential machines, you can ensure a purchase that aligns with your production goals and budget constraints. Remember, a well-chosen milling machine not only enhances your shop’s capabilities but also contributes positively to achieving greater precision and efficiency in your projects.