Exploring the Benefits of Laser Welding for Sale

Understanding Laser Welding

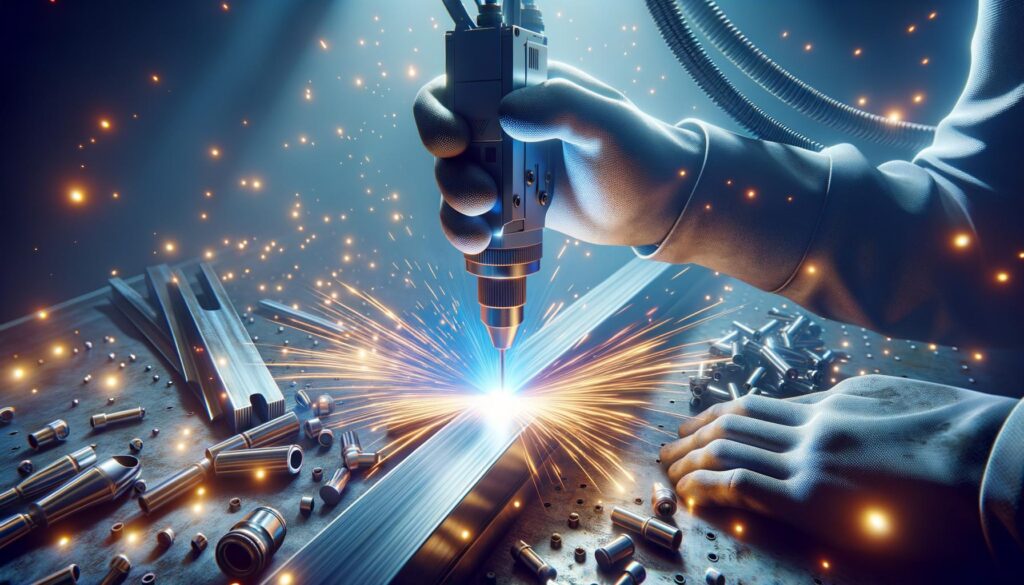

Laser welding is a cutting-edge technology that uses a concentrated beam of light to join materials, typically metals, with exceptional precision and strength. This method is renowned for its ability to produce high-quality welds with minimal distortion, making it a preferred choice across various industries. The process involves focusing a laser beam onto the materials’ surfaces, causing them to melt and fuse together as the beam moves along the joint. One of the standout features of laser welding is its adaptability; it can be used on a wide range of materials, from stainless steel and aluminum to exotic alloys, making it highly versatile.

The key advantage of laser welding lies in its precision. The ability to control the laser’s intensity, duration, and focus allows for welds that are not only strong but also aesthetically pleasing. This accuracy reduces the need for post-welding treatments, saving both time and resources. Furthermore, the speed of laser welding is unmatched, providing a rapid and efficient solution for high-volume production environments. As industries continue to demand faster and more reliable manufacturing processes, laser welding is increasingly becoming a vital tool in the manufacturing toolkit.

Applications Across Industries

Laser welding finds applications across a diverse range of industries, each benefiting from its unique capabilities. In the automotive sector, for instance, laser welding is used to join car body panels, engine components, and even intricate parts within the electrical systems. The precision and strength of the welds ensure the durability and safety of the vehicles, while the speed of the process aligns perfectly with the industry’s high production demands.

In the aerospace industry, where safety and reliability are paramount, laser welding is employed to fabricate critical components such as turbine blades and structural parts. The technology’s ability to produce lightweight yet robust joints is crucial in this field, where every gram counts. Additionally, the medical device industry leverages laser welding for manufacturing intricate components like surgical instruments and implants, where precision and sterility are non-negotiable.

Advantages of Purchasing Laser Welding Equipment

For businesses considering the acquisition of laser welding equipment, there are numerous advantages to consider. Firstly, the investment in this technology can lead to significant cost savings in the long term. The precision and speed of laser welding reduce material waste and lower labor costs, as fewer operators are needed to oversee the process. Moreover, the quality of the welds often eliminates the need for secondary processing, such as grinding or polishing, further cutting down on production time and expenses.

Another compelling reason to invest in laser welding equipment is its adaptability. With the ability to work on various materials and in different configurations, businesses can expand their capabilities and enter new markets. Additionally, the technology’s environmental benefits cannot be overlooked. Laser welding produces less waste and requires fewer consumables compared to traditional welding methods, aligning with the growing trend towards sustainable manufacturing practices.

Choosing the Right Laser Welding System

Selecting the appropriate laser welding system for your needs involves considering several factors:

- Material Compatibility: Ensure the system can handle the materials you work with.

- Power Requirements: Match the laser’s power output to your production needs.

- System Flexibility: Look for systems that offer adjustable settings for different applications.

- Support and Maintenance: Choose a supplier that offers robust support and maintenance services.

By carefully evaluating these aspects, businesses can ensure that their investment in laser welding technology provides maximum returns.

The Future of Laser Welding

As technology continues to advance, the future of laser welding looks promising. Innovations in laser technology are making systems more efficient, compact, and user-friendly. Automation is also playing a significant role, with robotic laser welding systems becoming more prevalent, further increasing productivity and precision. As industries continue to evolve and demand more sophisticated manufacturing solutions, laser welding is poised to play an even more critical role.

In summary, laser welding offers a multitude of benefits for businesses looking to enhance their production capabilities. Its precision, speed, and versatility make it an attractive option for various industries, while its cost-effectiveness and environmental advantages further solidify its position as a leading welding technology. For those considering investing in laser welding equipment, the potential for growth and innovation is boundless, making it a worthy addition to any manufacturing operation.